Your cart is currently empty!

Understanding the Predetermined Overhead Rate in Business

By understanding its mechanics, businesses can improve financial planning and maintain accurate product costing. If you’re new to managerial accounting, mastering POHR is a crucial step toward financial proficiency. As someone who has spent years working in accounting and financial management, I know how confusing overhead allocation can be for beginners. One of the most fundamental yet misunderstood concepts is the predetermined overhead rate (POHR). In this guide, I break down what it is, why it matters, and how businesses use it to allocate costs accurately. As a business owner, managing costs is crucial to maintaining profitability and staying ahead of the competition.

4: Compute a Predetermined Overhead Rate and Apply Overhead to Production

That is, if the predetermined overhead rate turns out to be inaccurate and the sales and production decisions are made based on this rate, then the decisions will be faulty. When there is a big difference between the actual and estimated overheads, unexpected expenses will definitely be incurred. Also, profits will be affected when sales and production decisions are based on an inaccurate overhead rate. Before the beginning of any accounting year, it is determined to estimate the level of activity and the amount of overhead required to allocate the same.

Calculating the Predetermined Overhead Rate

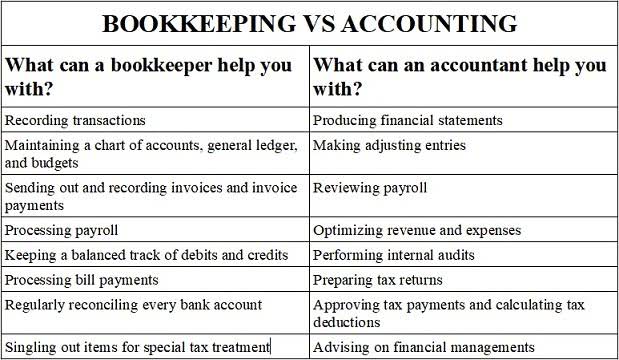

Overhead costs are then allocated to production according to the use of that activity, such as the number of machine setups needed. In contrast, the traditional allocation method commonly uses cost drivers, such as direct labor or machine a predetermined overhead rate includes hours, as the single activity. This $4 per hour overhead rate would then be applied to the number of direct labor hours for each job to allocate overhead costs.

Real-World Application: A Manufacturing Case Study

- This option is best if you have some idea of your costs but don’t have exact numbers.

- A predetermined overhead rate is often an annual rate used to assign or allocate indirect manufacturing costs to the goods it produces.

- Instead of waiting until the end of an accounting period to assign overhead, companies use POHR to distribute these costs in real time.

- This ensures work-in-process and finished goods inventory are reported at full absorption cost on financial statements.

- A predetermined overhead rate is an estimated amount of overhead costs that will be incurred during a set period of time.

- This allocation can come in the form of the traditional overhead allocation method or activity-based costing..

- A pre-determined overhead rate is the rate used to apply manufacturing overhead to work-in-process inventory.

The activity base (also known as the allocation base or activity driver) in the formula for predetermined overhead rate is often direct labor costs, direct labor hours, or machine hours. That is, a number of possible allocation bases such as direct labor hours, direct labor dollars, or machine hours can be used for the denominator of the predetermined overhead rate equation. Commonly used allocation bases are direct labor hours, direct labor dollars, machine hours, and direct materials cost incurred by the process. This activity base is often direct Mental Health Billing labor hours, direct labor costs, or machine hours.

Using the POHR

- Using the planned annual amounts for the upcoming year reduces the fluctuations that would occur if monthly rates were used.

- The overhead rate is a cost allocated to the production of a product or service.

- This can help to keep costs in check and to know when to cut back on spending in order to stay on budget.

- It’s also important to note that budgeted figures in calculating overhead rates are used due to seasonal fluctuation/expected changes in the external environment.

Analyzing overhead rates by department in this manner helps identify problem areas and opportunities to improve profitability. Knowing the overhead cost per unit allows the business to set competitive pricing while still covering their indirect expenses. Rather than lump overhead costs into one expense account, businesses should allocate fixed and variable overhead to departments. Calculating overhead rates accurately is critical, yet often confusing, for businesses. Hence, the fish-selling businesses need to monitor the seasonal variations and adjust the cost pattern of the products.

Steps in Using Predetermined Overhead Rates

Understanding how the predetermined overhead rate works can improve budgeting, pricing strategies, and cost control. Overhead costs are ongoing business expenses not directly tied to creating a product or service, such as factory rent or utility bills. These indirect costs make determining the true cost of goods produced challenging.

In some industries, the company has no control over the costs it must pay, like tire disposal fees. To ensure that the company is profitable, an additional cost is added https://colegiosoberana.com.br/2023/04/10/what-are-non-manufacturing-overhead-costs/ and the price is modified as necessary. In this example, the guarantee offered by Discount Tire does not include the disposal fee in overhead and increases that fee as necessary. The movie industry uses job order costing, and studios need to allocate overhead to each movie. Their amount of allocated overhead is not publicly known because while publications share how much money a movie has produced in ticket sales, it is rare that the actual expenses are released to the public.

Operating Expenses Vs Overhead Expenses

The company estimates that it will produce 10,000 units and that the total direct labor hours for the production will be 5,000 hours. The price a business charges its customers is usually negotiated or decided based on the cost of manufacturing. This means that once a business understands the overhead costs per labor hour or product, it can then set accurate pricing that allows it to make a profit. Hence, one of the major advantages of predetermined overhead rate formula is that it is useful in price setting. For example, the total direct labor hours estimated for the solo product is 350,000 direct labor hours. With $2.00 of overhead per direct hour, the Solo product is estimated to have $700,000 of overhead applied.